What Is Machine Guarding and Why Is It Important?

Do you work with machines? According to the U.S. Centers for Disease Control and Prevention (CDC), over a quarter-million workers sustain a severe machine-related injury each year. Whether it's a lathe, press, mill or any other machine, though, guarding can lower the risk of bodily injury. Machine guarding is an invaluable element of all heavy machinery. What is machine guarding exactly, and why is it important?

Overview of Machine Guarding

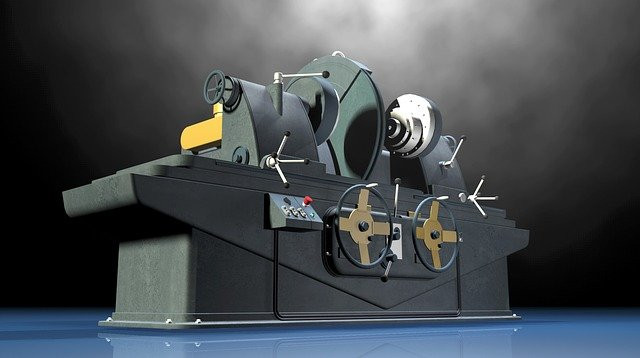

Machine guarding consists of the barriers, rails and other protective solutions that are designed to protect workers from injury when using a machine. They are typically found in front of the machine's moving parts. Rather than being exposed, the machine's moving parts are covered with guarding. Guarding serves as a physical barrier between workers and the machine's moving parts.

The Importance of Machine Guarding

Machine guarding is important because it protects workers from bodily injuries. Countless businesses use machines in their respective workplace. With machine guarding, workers can safely operate these machines while minimizing their risk of bodily injuries.

Machine guarding can protect workers from a variety of different injuries. Different machines, of course, perform different tasks. Some machines cut workpieces, whereas others drill or shape workpieces. Regardless, exposure to a machine's moving parts may result in bodily injury. If your hand comes into contact with a machine's bladed tool, for instance, you may sustain a laceration that requires medical treatment.

To protect against lacerations and other types of bodily injury, you should use machine guarding. Machine guarding will create a barrier between the moving parts of a machine and yourself or other workers. Therefore, even if you accidentally pump against a moving part, you shouldn't sustain an injury. The machine guarding will shield you from the moving part.

The U.S. Occupational Safety and Health Administration (OSHA) requires the use of machine guarding. Found in standard 1910.212, OSHA states that machines must have guarding to protect workers from operational hazards. Employers who fail to use machine guarding are a risk of a violation, which can lead to fines and other enforcement actions.

In Conclusion

If you come into contact with a machine's moving parts, you could sustain a serious bodily injury. Fortunately, there are solutions available to protect against such injuries. Known as machine guarding, it's commonly found on commercial machinery. Machine guarding creates a barrier between the moving parts of a machine and the workers who use it.

Recent Posts

-

Fire Safety in the Workplace: What You Need to Know

What steps are you taking to prevent fires in your workplace? According to the U.S. Occupational Saf …Aug 23rd 2023 -

Is It Safe to Go Jogging With a Cold Infection?

If you're suffering from a cold infection, you might be wondering whether it's safe to go jogging. T …Aug 22nd 2023 -

5 Safety Tips to Follow When Using a Powder-Actuated Tool

Powder-actuated tools are commonly used to join materials to steel and concrete. Also known as Hilti …Aug 20th 2023